Adhesive wear mechanisms in the presence of weak interfaces: Insights from an amorphous model system

Whenever surfaces in contact slide relative to each other, they wear and emit particles. Understanding this process at the microscopic scale is an important piece of the puzzle to figuring out how exactly materials and parts wear out and to ultimately extend their useful lifetime. In our efforts in the Computational Solid Mechanics Laboratory at EPFL to tackle the problem of wear—as a part of the field of tribology—we used molecular dynamics (MD) simulations to understand the creation of wear particles when the adhesion between the surfaces is reduced—a case that is in fact expected in most material contacts. The work shows at the microscopic level why flatter surfaces are more amenable to slip and low wear and, conversely, wear particles result more easily from high-angle asperity collisions on rougher surfaces. All of this can be described by a predictive, analytical model at the asperity level based on interface properties and roughness parameters.

If you want to get to the details of the study, it can be found here (click here for a free and legal download):

T. Brink and J.-F. Molinari, Adhesive wear mechanisms in the presence of weak interfaces: Insights from an amorphous model system, Phys. Rev. Mater. 3, 053604 (2019).

If you do not understand anything, but are intrigued, I will attempt a short introduction to what we are doing here. One first has to know that surfaces are usually rough at microscopic length scales, even when they look perfectly flat to the human eye. This phenomenon is so common that one has to go to extraordinary lengths to create something really smooth. The consequence is that objects that come into contact are never truly in contact everywhere they seem to be:

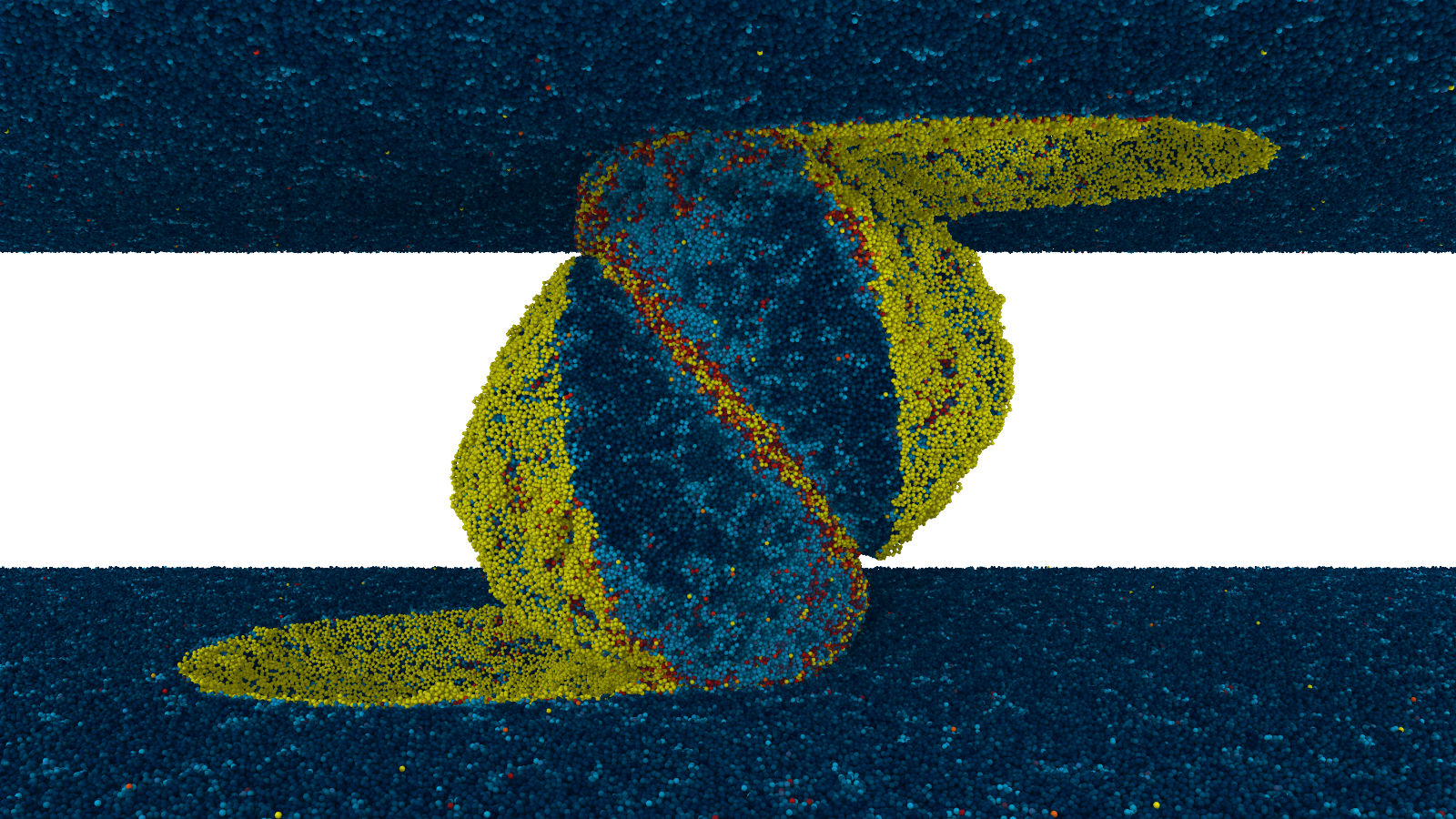

As shown above, they are only in contact in some areas that protrude from the surface, called asperities. Due to adhesive forces between the atoms on both sides, the contacting asperities stick together. When the surfaces keep sliding against each other, these areas get deformed and damaged. The question that we want to answer is when this damage leads to the detachment of some material—a process that will (hopefully slowly) wear down the surface. In our work we use MD simulations that capture the behaviour of a material at the scale of atoms. The image at the beginning shows a detached particle from our calculations. The main novelty of this work is that we consider a wider range of parameter, such as the material properties, the strength of the adhesion between the bodies, and the angle at which the surface asperities meet. We hope that if we keep refining our understanding of these processes that we can one day predict the wear rates of real materials given just a few easily measurable parameters—a feat that is surprisingly hard to accomplish and that has largely remained elusive.